The Total System Assurance Journey

Working with you, BSC integrates the four operational pillars:

- Plant

- People

- Process

- Premises

with our four key stages of work. So that together we understand the factors that create success in your organisation.

This approach provides you with a better understanding of what it is critically important to manage. So that you know in detail, what could jeopardise success.

This means that together we identify what determines the levels of risk.

This often uncovers surprising dependencies that are seemingly unconnected yet hold the power to jeopardise success.

``A new model of what should be in place to achieve success``

Operational Assurance

- The 4 P’s (Plant, Premises, People and Process) are at the heart of BSC’s Operational Assurance Service. For operational excellence each ‘P’ must be considered and optimised. The best people working with aging or poor condition plant will lead to operational issues. New or good condition plant being operated by people without the required processes, procedures, awareness and training will also cause operational issues.

- BSC act as our clients representative while examining the plant, the facility and the service providers operational processes and procedures related to the mechanical and electrical infrastructure within the facility.

- Our independent, impartial benchmarking reviews and operational assurance programmes have helped our clients around the globe improve their operational delivery and provide a roadmap to operational excellence.

The four key stages of the Operational Assurance Journey are:

- Stage 1 – Understanding – what’s important for success

- Stage 2 – Focus – define the key areas

- Stage 3 – Profiling – In depth investigation and analysis

- Stage 4 – Continuous Improvement – building towards operational excellence

Stage 1: Understanding – what’s important for success

Objective:

Achieve clarity on the focus of work for all stakeholders

Key Benefit:

Greater awareness of the factors that create success

Stage 2: Focus – define the key areas

Objective:

Clarity on the project and purpose for key stakeholders and operational teams

Key Benefit:

Understand the potential to make better informed decisions

Stage 3: Profiling – In depth investigation and analysis

Objective:

Benchmark performance against agreed success criteria

Key Benefits:

Create the basis for continual improvement including:

- Raise operational delivery standards

- Demonstrate governance

- Improve business resilience

- Increase collective understanding of critical activities so that everyone works better together

Stage 4: Continuous Improvement – building towards operational excellence

Objective:

Continuous improvement of agreed success criteria

Key Benefit:

Greater success through aligning goals, roles and responsibilities

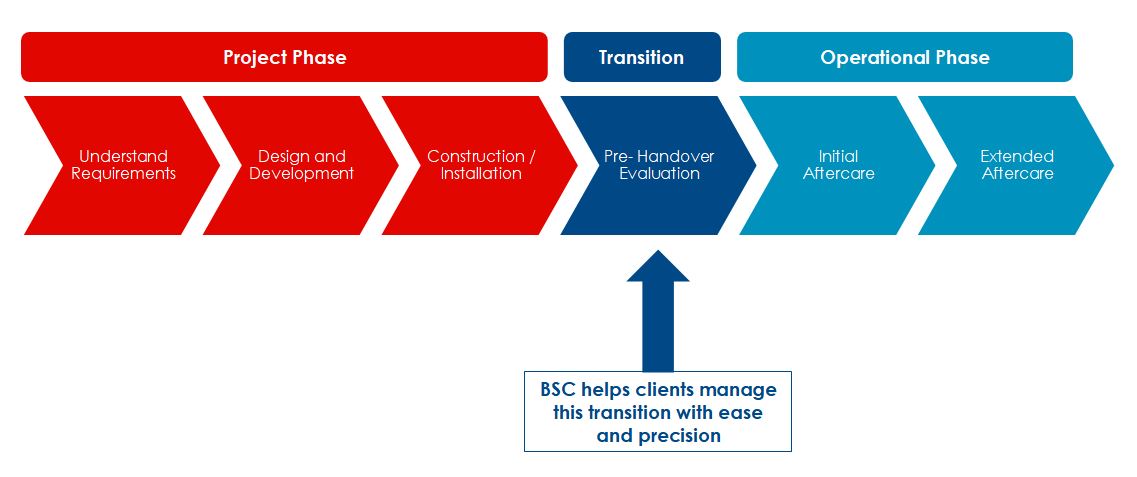

Operational Preparedness

What is Operational Preparedness?

- The success of a construction project goes beyond completing the project on time, on specification and on budget. The true measure of success is achieving the operational vision for the facility and allowing the facility to be utilised to its fullest potential.

- Operational Preparedness ensures that the operational team has the awareness, knowledge, skills, information and operational training required to realise the operational vision, and to successfully operate the facility from the outset and beyond.

Operational Preparedness – the BSC approach

- Working across the project life cycle, BSC works with the client, the project team and the operational team to ensure the requirements and needs of the respective stakeholders are understood. Then to ensure that those needs are met as part of the smooth transition from project phase to operations